DOMESTIC MEMBRANE

Reverse Osmosis is a process in which dissolved inorganic solids (such as salts) are removed from a solution (such as water). This is accomplished by household water pressure pushing the tap water through a semi permeable membrane. The membrane (which is about as thick as cellophane) allows only the water to pass through, not the impurities or contaminates. These impurities and contaminates are flushed down the drain.

Ultimately the factors that affect the performance of a Reverse Osmosis System are:

- Incoming water pressure

- Water Temperature

- Type and number of total dissolved solids (TDS) in the tap water

- The quality of the filters and membranes used in the RO System (see operating specs)

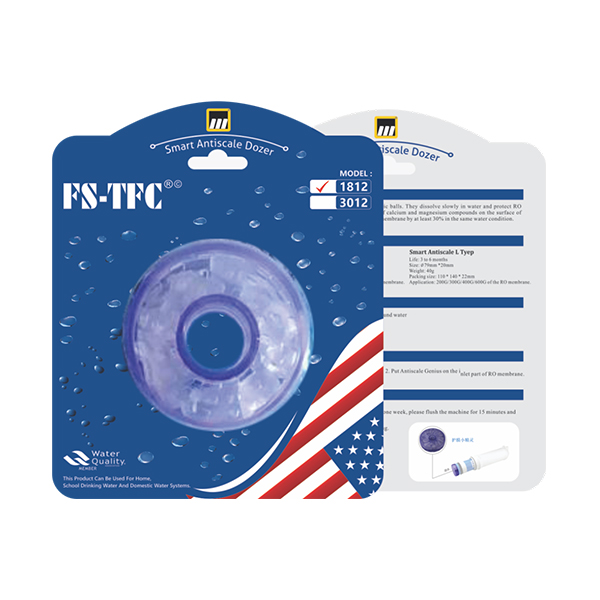

- Big Flow and Hi-Rejection Domestic membrane

- Big Flow membrane sheet specially for Indian market

- Unique rolling technology